Assembling and fastening materials together require various tools and techniques. One such technique is riveting. Rivets are fasteners that play a crucial role in securely joining two pieces of metal or other materials. They are inexpensive, easy to use, and ideal for many applications. In this blog, we will discuss what rivets are, their dimensions, properties and uses, and the different types of rivets available.

What is Rivets?

A rivet is a permanent mechanical fastener that joins two materials together. It typically has a cylindrical shape with a head on one end and a tail on the other end. The head provides a bearing surface that helps distribute the load, while the tail forms the second head to keep the rivet in place. Rivets are made from various materials, such as aluminium, steel, brass, copper, and titanium. They come in different sizes, shapes and finishes to suit various applications.

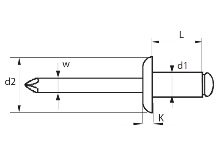

Rivets Dimensions

| d1 dia. | L | Drill Size | d2 dia. | K | w dia. | Grip Range |

| 2.4mm | 4.0mm | 2.5mm | 5.0mm | 0.6mm | 1.45mm | 0.5mm – 2.0mm |

| 2.4mm | 6.0mm | 2.5mm | 5.0mm | 0.6mm | 1.45mm | 2.0mm – 4.0mm |

| 2.4mm | 8.0mm | 2.5mm | 5.0mm | 0.6mm | 1.45mm | 4.0mm – 6.0mm |

| 2.4mm | 10.0mm | 2.5mm | 5.0mm | 0.6mm | 1.45mm | 6.0mm – 8.0mm |

| 2.4mm | 12.0mm | 2.5mm | 5.0mm | 0.6mm | 1.45mm | 8.0mm – 9.5mm |

| d1 dia. | L | Drill Size | d2 dia. | K | w dia. | Grip Range |

| 3.0mm | 4.0mm | 3.1mm | 6.0mm | 1.0mm | 1.8mm | 0.5mm – 1.5mm |

| 3.0mm | 5.0mm | 3.1mm | 6.0mm | 1.0mm | 1.8mm | 0.5mm – 2.5mm |

| 3.0mm | 6.0mm | 3.1mm | 6.0mm | 1.0mm | 1.8mm | 1.5mm – 3.5mm |

| 3.0mm | 7.0mm | 3.1mm | 6.0mm | 1.0mm | 1.8mm | 1.5mm – 4.5mm |

| 3.0mm | 8.0mm | 3.1mm | 6.0mm | 1.0mm | 1.8mm | 3.5mm – 5.0mm |

| 3.0mm | 9.0mm | 3.1mm | 6.0mm | 1.0mm | 1.8mm | 4.5mm – 6.0mm |

| 3.0mm | 10.0mm | 3.1mm | 6.0mm | 1.0mm | 1.8mm | 5.0mm – 7.0mm |

| 3.0mm | 12.0mm | 3.1mm | 6.0mm | 1.0mm | 1.8mm | 7.0mm – 9.0mm |

| 3.0mm | 14.0mm | 3.1mm | 6.0mm | 1.0mm | 1.8mm | 9.0mm – 11.0mm |

| 3.0mm | 16.0mm | 3.1mm | 6.0mm | 1.0mm | 1.8mm | 11.0mm – 13.0mm |

Rivets Properties

Rivets have several beneficial properties, making them an ideal fastener choice for many industrial applications. First, they are strong, reliable, and permanent. They can withstand high tension and compression, making them ideal for heavy-duty applications. Second, rivets are resistant to vibration, corrosion, and heat, making them perfect for harsh environments. Third, rivets are easy to install and require no special tools or skills other than a hammer.

Rivets Types

There are different types of rivets available to suit different applications. The most common type is the solid rivet, a cylindrical shaped rivet with a solid shank. The solid rivet requires a hole to be predrilled in the material to be joined before installation. Another common type is the blind rivet, which requires no hole drilling but can only be installed from one side of the workpiece. Other rivets include tubular, split, and drive rivets, each with unique features and installation processes.

Rivets Uses

Rivets are used in various applications, such as in aircraft, automobiles, construction, marine, and electronic industries. In the automotive industry, rivets join panels, structural components, and frames. The aerospace industry also uses rivets extensively as they offer a permanent and secure fastening method for the plane’s structure. Rivets are also used in construction for metal roofing and siding installation. They are also used in marine applications, such as boat building and ship repair, where they offer excellent resistance to corrosion and other environmental factors.

Conclusion:

In conclusion, rivets are a versatile and efficient fastening method in various applications. They provide a secure and robust joint between materials and are permanent and simple to install. Understanding the properties, dimensions and types of rivets available for specific applications can help select the most appropriate rivet for the job. With their strength, durability, and versatility, rivets are unquestionably the most popular and widespread type of fastener.

Hey, I’m Krutik, a casual blogger expert in the metal industry. I am passionate about providing valuable information to my readers. With a background in engineering and construction, I like playing Cricket & watching Netflix shows in my free time. Thank you for visiting my blog, and I hope you find my information helpful!