A split washer is a type that is split at one point and is commonly used in building and construction work. It creates tension between two nuts and bolts to keep them from loosening up. They are available in various sizes, materials, and configurations to suit your needs, making them the perfect choice for various applications. This post will take a closer look at split washers – their dimensions and properties- and explore some of the common areas in which they are used.

What is Split Washer?

A split washer is a fastener designed to distribute load pressure over a larger area than traditional washers. It usually consists of two halves, each with its hole and an attached split. This design allows the split washer to be compressed when screwed down, providing increased torque exertion, which helps prevent loosening due to vibration or impacts. Split washers are commonly used in construction, assembly lines, machine maintenance and repair projects. They are also an essential component for electrical connections as they help ensure a snug fit along with prevention against arcing and sparking due to frequent variations in voltage.

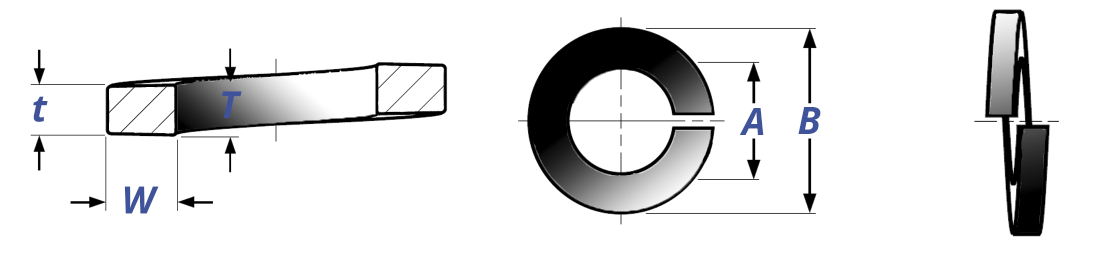

Split Washers Dimensions:

| Regular & High Alloy Split Helical Spring Lock Washers (ASME B18.21.1-1999) | ||||||

|---|---|---|---|---|---|---|

| Nominal Washer Size

Click on the size to shop products |

A | B | (T+t) 2 |

W | ||

| Inside Diameter (ID) | Outside Diameter (OD) | Mean Section Thickness | Section Width | |||

| Max | Min | Max | Min | Min | ||

| #2 | 0.086 | 0.094 | 0.088 | 0.172 | 0.020 | 0.035 |

| #3 | 0.099 | 0.107 | 0.101 | 0.195 | 0.025 | 0.040 |

| #4 | 0.112 | 0.120 | 0.114 | 0.209 | 0.025 | 0.040 |

| #5 | 0.125 | 0.133 | 0.127 | 0.236 | 0.031 | 0.047 |

| #6 | 0.138 | 0.148 | 0.141 | 0.250 | 0.031 | 0.047 |

| #8 | 0.164 | 0.174 | 0.167 | 0.293 | 0.040 | 0.055 |

| #10 | 0.190 | 0.200 | 0.193 | 0.334 | 0.047 | 0.062 |

| #12 | 0.216 | 0.227 | 0.220 | 0.377 | 0.056 | 0.070 |

| 1/4 | 0.250 | 0.260 | 0.252 | 0.487 | 0.062 | 0.109 |

| 5/16 | 0.312 | 0.322 | 0.314 | 0.583 | 0.078 | 0.125 |

| 3/8 | 0.375 | 0.385 | 0.377 | 0.680 | 0.094 | 0.141 |

| 7/16 | 0.438 | 0.450 | 0.440 | 0.776 | 0.109 | 0.156 |

| 1/2 | 0.500 | 0.512 | 0.502 | 0.869 | 0.125 | 0.171 |

| 9/16 | 0.562 | 0.574 | 0.564 | 0.965 | 0.141 | 0.188 |

| 5/8 | 0.625 | 0.641 | 0.628 | 1.073 | 0.156 | 0.203 |

| 3/4 | 0.750 | 0.766 | 0.753 | 1.265 | 0.188 | 0.234 |

| 7/8 | 0.875 | 0.894 | 0.878 | 1.459 | 0.219 | 0.266 |

| 1 | 1.000 | 1.024 | 1.003 | 1.656 | 0.250 | 0.297 |

| 1-1/8 | 1.125 | 1.153 | 1.129 | 1.847 | 0.281 | 0.328 |

| 1-1/4 | 1.250 | 1.280 | 1.254 | 2.036 | 0.312 | 0.359 |

| 1-3/8 | 1.375 | 1.408 | 1.379 | 2.219 | 0.344 | 0.391 |

| 1-1/2 | 1.500 | 1.534 | 1.504 | 2.419 | 0.375 | 0.422 |

| 1-3/4 | 1.750 | 1.789 | 1.758 | 2.679 | 0.389 | 0.424 |

| 2 | 2.000 | 2.039 | 2.008 | 2.936 | 0.422 | 0.427 |

Split Washers Properties:

Split washers have certain properties that make them ideal for holding fasteners tightly into place. They are made of materials such as stainless steel, high-carbon steel, and brass, which are corrosion-resistant and provide durability. Some split washers have zinc or phosphate coating, giving them a longer lifespan.

One unique property that a split washer possesses is that it exerts constant pressure on the mating surfaces, thus enabling them to grip tightly. Moreover, they are essential in shock-resistant applications and can absorb the impact of a sudden force on the fasteners.

Split Washers Uses:

Split washers are frequently used in machinery, plumbing, automotive repair, electrical installations, and other applications that require a fastener that won’t loosen. They are typically used with bolts, screws, and nuts for various applications. In machines, a split washer’s primary function is preventing parts’ loosening due to vibrations and shock. They are essential in electrical installations as the vibrations can cause wires to jiggle and loosen up, causing short circuits.

Types of Split Washers:

There are two types of split washers – plain and spring. Plain split washers have a flat profile and a single point of separation, while spring split washers have a slight contour and several teeth that exert constant pressure. Spring split washers are prone to breakage since they are more rigid but ideal where high loads are involved. Plain split washers are malleable and flexible, making them ideal for most applications with low to moderate loads.

How to Use Split Washers:

To use a split washer, place it between the two components where the nut and bolt meet. The washer’s split end should face the nut, and the other end should be in contact with the surface of the material being attached. Tighten the nut on the bolt until it stops tightening. Then, apply an additional quarter turn to set the proper tension.

Conclusion:

In conclusion, split washers are essential in preventing the loosening of nuts and bolts in various applications. They can absorb impact and shock by exerting constant pressure on the mating surfaces to maintain their tight grip. By selecting the right size and type and properly installing them, you can optimize the use of split washers for your needs.

A passionate metal industry expert and blogger. With over 5 years of experience in the field, Palak brings a wealth of knowledge and insight to her writing. Whether discussing the latest trends in the metal industry or sharing tips, she is dedicated to helping others succeed in the metal industry.