Hex head screws, or hex bolts, are one of the most commonly used fasteners in construction and manufacturing. They are preferred over other types of screws due to their ability to provide a sturdy grip, even in challenging working environments. In this post, we’ll explore the dimensions, properties, and uses of hex head screws.

What is Hex Head Screws?

Hex Head Screws are a fastener typically used for assembling mechanical components. They have a hexagonal or six-sided head shape, making it easier to drive into materials than traditional screws with a more rounded head. Hex Head Screws come in various sizes and lengths, the most common being M3, M4 and M5 metric sizes. They are available in machine screw thread variants (hexagon socket cap screws) and self-tapping variants (hexagon self-drilling screws). Hex Head Screws can be made from steel, brass, aluminium, copper or other alloys, depending on their application requirements. These versatile fasteners can be used for everything from construction projects to hobbies such as model building, making them an essential part of any tool collection!

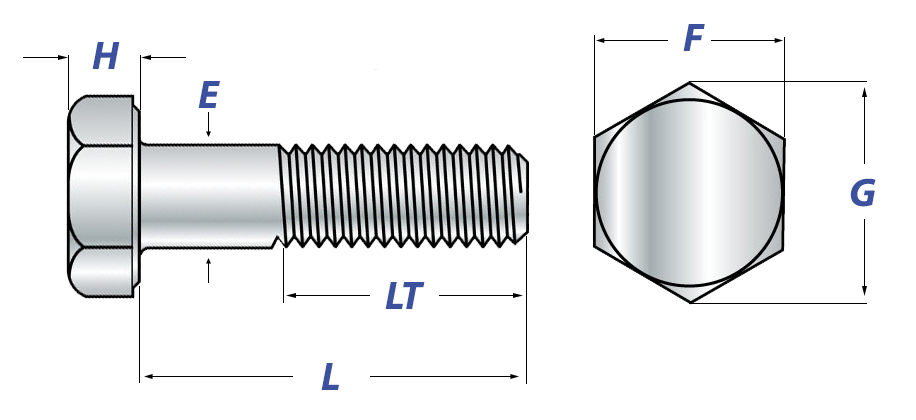

Hex Head Screws Dimensions:

| Hex Cap Screws: Head & Thread Dimensions | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal or Basic Product Diameter

Click on the size to shop products |

Body Diameter (E) | Width Across Flats (F) | Width Across Corners (G) | Head Height (H) | Thread Length (LT) | ||||||||

| Max | Min | Basic | Max | Min | Max | Min | Basic | Max | Min | <or=6″ | >6″ | ||

| 1/4 | .2500 | .2500 | .2450 | 7/16 | .438 | .428 | .505 | .488 | 5/32 | .163 | .150 | .750 | 1.000 |

| 5/16 | .3125 | .3125 | .3065 | 1/2 | .500 | .489 | .577 | .557 | 13/64 | .211 | .195 | .875 | 1.125 |

| 3/8 | .3750 | .3750 | .3690 | 9/16 | .562 | .551 | .650 | .628 | 15/64 | .243 | .226 | 1.000 | 1.250 |

| 7/16 | .4375 | .4375 | .4305 | 5/8 | .625 | .612 | .722 | .698 | 9/32 | .291 | .272 | 1.125 | 1.375 |

| 1/2 | .5000 | .5000 | .4930 | 3/4 | .750 | .736 | .866 | .840 | 5/16 | .323 | .302 | 1.250 | 1.500 |

| 9/16 | .5625 | .5625 | .5545 | 13/16 | .812 | .798 | .938 | .910 | 23/64 | .371 | .348 | 1.375 | 1.625 |

| 5/8 | .6250 | .6250 | .6170 | 15/16 | .938 | .922 | 1.083 | 1.051 | 25/64 | .403 | .378 | 1.500 | 1.750 |

| 3/4 | .7500 | .7500 | .7410 | 1-1/8 | 1.125 | 1.100 | 1.299 | 1.254 | 15/32 | .483 | .455 | 1.750 | 2.000 |

| 7/8 | .8750 | .8750 | .8660 | 1-5/16 | 1.312 | 1.285 | 1.516 | 1.465 | 35/64 | .563 | .531 | 2.000 | 2.250 |

| 1 | 1.0000 | 1.0000 | .9900 | 1-1/2 | 1.500 | 1.469 | 1.732 | 1.675 | 39/64 | .627 | .591 | 2.250 | 2.500 |

| 1-1/8 | 1.1250 | 1.1250 | 1.1140 | 1-11/16 | 1.688 | 1.631 | 1.949 | 1.859 | 11/16 | .718 | .658 | 2.500 | 2.750 |

| 1-1/4 | 1.2500 | 1.2500 | 1.2390 | 1-7/8 | 1.875 | 1.812 | 2.162 | 2.066 | 25/32 | .813 | .749 | 2.750 | 3.000 |

| 1-1/2 | 1.5000 | 1.5000 | 1.4880 | 2-1/4 | 2.250 | 2.175 | 2.598 | 2.480 | 1-5/16 | .974 | .902 | 3.250 | 3.500 |

Hex Head Screws Properties:

The material used to manufacture hex head screws will determine their strength and durability. Steel is the most commonly used material that can be treated to prevent corrosion and increase lifespan. Stainless steel hex head screws are another popular choice due to their corrosion-resistant properties. Hex head screws are designed to withstand high torque levels without getting damaged or breaking.

Hex Head Screws Uses:

Hex head screws are versatile and can be used in various applications. They are commonly used in construction for framing, roofing, and flooring. They are also used in manufacturing and assembly processes to fasten different components. Hex head screws are commonly used in automotive applications, marine and aerospace environments, and household repairs.

Hex Head Screws Advantages:

The hex head design has several advantages over other screw types. They are easy to install with a standard socket wrench and provide better torque transfer due to their six-sided shape. Hex head screws are also more resistant to stripping, providing better grip and preventing the screwdriver from slipping during installation.

Hex Head Screws Installation tips:

To ensure proper installation of hex head screws, it’s essential to use the right tools and techniques. Always use the correct socket wrench or driver size for the screw head. Use a torque wrench to tighten the screw to the recommended torque level to prevent overtightening, which can lead to damage or breakage. Ensure the screw’s threads align correctly with the surface to which it’s being fastened to prevent cross-threading.

Conclusion:

Hex head screws are essential in any construction or manufacturing project due to their versatility, durability, and ease of installation. Understanding their dimensions, properties, and uses will help you decide when choosing the right screw for your project. Remember to use the correct tools and techniques for proper installation to ensure optimal performance and longevity.

A passionate metal industry expert and blogger. With over 5 years of experience in the field, Palak brings a wealth of knowledge and insight to her writing. Whether discussing the latest trends in the metal industry or sharing tips, she is dedicated to helping others succeed in the metal industry.