Spacer ring flanges are essential components in any piping system. These flanges are designed to maintain proper distance between two flanges without affecting their sealing. They are highly efficient in reducing the bending moment on pipelines and thus prevent leakage. This blog will discuss the dimensions, uses, and types of spacer ring flanges.

What is Spacer Ring Flanges?

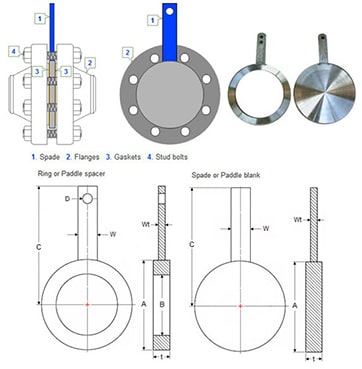

Spacer ring flanges are specialized flanges between two conventional piping components, such as valves and pumps, to provide space for insulation or thermal expansion. These flanges offer advantages over solid-type spacer rings due to their easy assembly and disassembly. They typically feature bolt holes, which allow them to be bolted directly onto other flange items without welding. Moreover, they are available in various sizes, materials and configurations, making them perfect for various applications.

Dimensions of Spacer Ring Flanges

|

NPS

|

Outside Ø

A |

Inside Ø

B |

Center to End

C |

Thickness

t |

Handle Width

W |

|

1/2

|

45

|

16

|

126

|

3

|

32

|

|

3/4

|

54

|

21

|

131

|

3

|

32

|

|

1

|

64

|

27

|

136

|

3

|

32

|

|

1¼

|

73

|

42

|

145

|

6.4

|

32

|

|

1½

|

83

|

48

|

145

|

6.4

|

32

|

|

2

|

102

|

61

|

155

|

6.4

|

32

|

|

2½

|

107

|

73

|

170

|

6.4

|

32

|

|

3

|

133

|

89

|

170

|

6.4

|

32

|

|

3½

|

159

|

102

|

202

|

9.7

|

38

|

|

4

|

172

|

114

|

202

|

9.7

|

38

|

|

5

|

194

|

141

|

225

|

9.7

|

38

|

|

6

|

219

|

168

|

225

|

12.7

|

38

|

|

8

|

276

|

219

|

267

|

12.7

|

38

|

|

10

|

337

|

273

|

322

|

15.7

|

44

|

|

12

|

406

|

324

|

357

|

19.1

|

44

|

|

14

|

448

|

356

|

378

|

19.1

|

44

|

|

16

|

511

|

406

|

410

|

22.4

|

44

|

|

18

|

546

|

457

|

427

|

25.4

|

51

|

|

20

|

603

|

508

|

455

|

28.4

|

51

|

|

24

|

714

|

610

|

512

|

31.8

|

51

|

|

NPS

|

Outside Ø

A |

Inside Ø

B |

Center to End

C |

Thickness

t |

Handle Width

W |

Uses

Spacer ring flanges are extensively used in piping systems where the distance between the two flanges needs to be maintained. They are highly efficient in reducing the bending moment on pipelines and thus prevent leakage. Spacer ring flanges are also used in cryogenic applications where temperature fluctuations can cause the metal to contract or expand, affecting pipe alignment. They are widely used in oil and gas, chemical, pharmaceutical, and power generation industries.

Types

Spacer ring flanges are available in various types to cater to different piping system requirements. The most common types of spacer ring flanges are:

Raised Face: These flanges have a gasket sealing surface above the bolting circle face.

Flat Face: These flanges have a flat gasket sealing surface parallel to the bolting circle face. They are used in applications where a metal-to-metal seal is required.

Ring Joint: These flanges have grooves machined into the flange face to accept a metal ring gasket. They are widely used in high-pressure and high-temperature applications.

Lap Joint: These flanges consist of two main parts: a stub end and a loose backing flange. The stub end is welded to the pipe, and the flange can rotate freely on the stub end, facilitating easy alignment.

Material

Spacer ring flanges are manufactured using materials ranging from common carbon steel to exotic metals like nickel alloys, titanium, and zirconium. The material selection depends on the piping system’s pressure, temperature, and process requirements.

Installation

Spacer ring flanges are easy to install and use. They can be placed between two flanges and secured using bolts and gaskets. The bolt torque specifications and gasket materials should be chosen carefully to prevent leakage.

Conclusion:

Spacer ring flanges are essential in a piping system, enhancing longevity, performance, and efficiency. From their dimensions and uses to the different types and material selection, understanding spacer ring flanges is crucial to optimize pipe performance and prevent leaks. With the information in this blog, we hope you can select the right spacer ring flange for your specific piping system needs.

A passionate metal industry expert and blogger. With over 5 years of experience in the field, Palak brings a wealth of knowledge and insight to her writing. Whether discussing the latest trends in the metal industry or sharing tips, she is dedicated to helping others succeed in the metal industry.