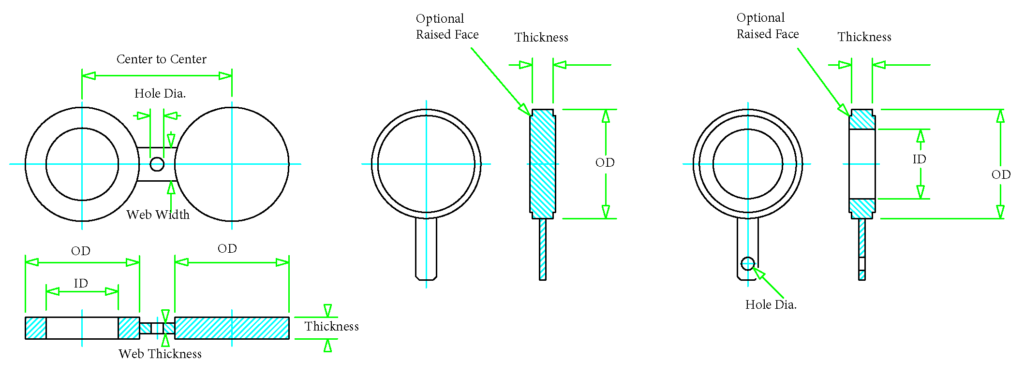

Flanges are essential components in various industrial applications. One of the most common flanges used in industries is the spectacle blind flange. This flange is unique due to its ability to combine two different flanges – the blind flange and the spacer flange. This blog post will explore the different dimensions, uses, and types of spectacle blind flanges.

What is Spectacle Blind Flanges?

Spectacle blind flanges are speciality pipe fittings used to seal piping systems. They provide an additional level of safety, as they can isolate upstream and downstream pressure when a valve is malfunctioning or under maintenance. Spectacle blinds consist of two gaskets that fit together like a pair of eyeglasses, with the flanges designed to accept bolts for installation onto existing pipelines. These flanges can handle higher temperatures and pressures than standard weld-neck flanges, making them ideal for industrial applications such as oil refineries and power plants.

Dimensions of Spectacle Blind Flanges

| Size in Inch | Size in MM | Internal Dia. | Outer Dia. | Center to Center | Thick. | Web Width | Web Thick. | Hole Dia | Spec. Blind Weight in Kg | Paddle Blank Weight in kg | Paddle Spacer Blank Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 15 | 16 | 45 | 60 | 3 | 38 | 2 | 15.875 | 0.07 | 0.03 | 0.03 |

| 3/4 | 20 | 21 | 54 | 70 | 3 | 38 | 2 | 15.875 | 0.1 | 0.05 | 0.04 |

| 1 | 25 | 27 | 64 | 80 | 3 | 38 | 2 | 15.875 | 0.14 | 0.07 | 0.06 |

| 1 1/4 | 32 | 42 | 73 | 90 | 6.4 | 38 | 4 | 15.875 | 0.35 | 0.21 | 0.14 |

| 1 1/2 | 40 | 48 | 83 | 100 | 6.4 | 38 | 4 | 15.875 | 0.46 | 0.27 | 0.18 |

| 2 | 50 | 61 | 102 | 120 | 6.4 | 51 | 4 | 19.05 | 0.68 | 0.41 | 0.26 |

| 2 1/2 | 65 | 73 | 107 | 140 | 6.4 | 51 | 4 | 19.05 | 0.7 | 0.46 | 0.24 |

| 3 | 80 | 89 | 133 | 150 | 6.4 | 64 | 4 | 19.05 | 1.1 | 0.71 | 0.39 |

| 3 1/2 | 90 | 102 | 159 | 175 | 9.7 | 64 | 5 | 19.05 | 2.44 | 1.54 | 0.9 |

| 4 | 100 | 114 | 172 | 190 | 9.7 | 64 | 5 | 19.05 | 2.81 | 1.8 | 1.01 |

| 5 | 130 | 141 | 194 | 215 | 9.7 | 76 | 5 | 22.225 | 3.37 | 2.29 | 1.08 |

| 6 | 150 | 168 | 219 | 240 | 12.7 | 76 | 7 | 22.225 | 5.39 | 3.82 | 1.57 |

| 8 | 200 | 219 | 276 | 300 | 12.7 | 76 | 10 | 22.225 | 8.32 | 6.07 | 2.25 |

| 10 | 250 | 273 | 337 | 360 | 15.7 | 102 | 12 | 25.4 | 15.04 | 11.19 | 3.84 |

| 12 | 300 | 324 | 406 | 430 | 19.1 | 102 | 15 | 25.4 | 26.95 | 19.77 | 7.18 |

| 14 | 350 | 356 | 448 | 475 | 19.1 | 108 | 15 | 28.575 | 32.94 | 24.07 | 8.87 |

| 16 | 400 | 406 | 511 | 540 | 22.4 | 108 | 17 | 28.575 | 50.27 | 36.73 | 13.54 |

| 18 | 450 | 457 | 546 | 580 | 25.4 | 114 | 20 | 31.75 | 61.79 | 47.55 | 14.23 |

| 20 | 500 | 508 | 603 | 635 | 28.4 | 121 | 22 | 31.75 | 83.67 | 64.85 | 18.82 |

| 24 | 600 | 610 | 714 | 750 | 31.8 | 140 | 24 | 34.925 | 129.3 | 101.8 | 27.49 |

Uses of Spectacle Blind Flanges

Spectacle blind flanges are primarily used in applications requiring pipeline maintenance or modification. They are used to temporarily or permanently block off sections of pipelines to allow for maintenance or inspection without shutting down the entire system. They can also regulate flow by alternating between the open and closed positions, making them useful in high-pressure systems.

Types of Spectacle Blind Flanges

There are three main types of spectacle blind flanges. The first type is the slip-on spectacle blind flange, which is slid onto a pipe and welded on both sides. The second type is the weld-neck spectacle blind flange, which is welded to the pipe on one side and has a flange face on the other. The third type is the threaded spectacle blind flange, which is screwed onto a pipe and is commonly used in low-pressure applications.

Installation and Maintenance

Proper installation and maintenance of spectacle blind flanges are essential for effective use. A professional should install them and check them regularly for leaks or damage. During installation, ensuring that the flanges match the pipe specifications and that the gasket material is compatible with the process fluid is critical.

Conclusion:

Spectacle blind flanges are essential in various industries due to their unique design and functionality. They offer flexibility and convenience in pipeline maintenance, modification, and flow regulation. With the information presented in this blog post, you should now better understand spectacle blind flanges, their dimensions, uses, and types. When properly installed and maintained, spectacle blind flanges can help increase the efficiency and safety of pipeline systems.

A passionate metal industry expert and blogger. With over 5 years of experience in the field, Palak brings a wealth of knowledge and insight to her writing. Whether discussing the latest trends in the metal industry or sharing tips, she is dedicated to helping others succeed in the metal industry.