Blind flanges are commonly used in piping systems to seal off a pipe or vessel opening. This flange type is particularly useful when the pipe or vessel needs to be isolated from the rest of the system. Blind flanges come in different sizes, materials, and types. This post provides information on the dimensions, uses, and types of blind flanges.

What is Blind Flanges?

Blind Flanges are pipe flanges with no openings to seal a pipeline or blank off the end of a branch connection. They are most commonly manufactured from stainless steel, duplex or super duplex steel for greater strength and corrosion resistance. They typically come with raised faces, serrated gasket surfaces, and tapped bolt holes for easy installation. Blind flanges can also be supplied in any material as per customer requirements.

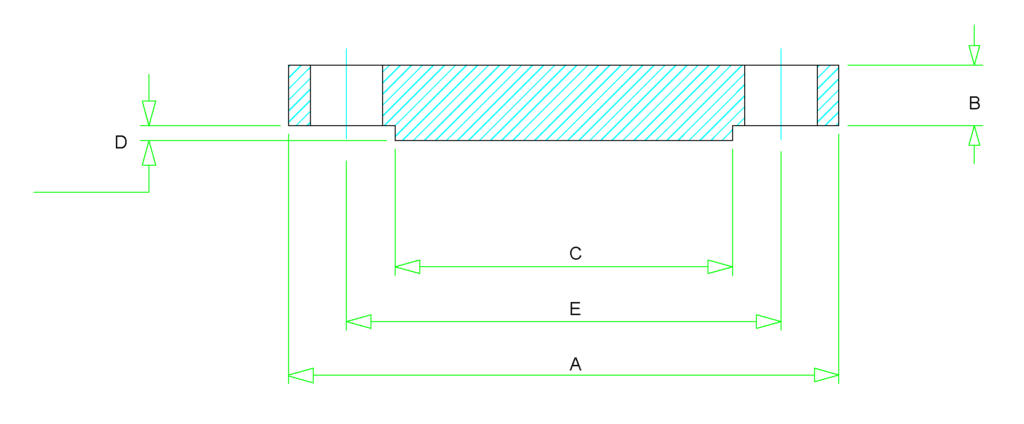

Dimensions of Blind Flanges

| Size in Inch |

Size in mm |

Outer Dia. |

Flange Thick. |

RF Dia. |

RF Height |

PCD | No of Bolts |

Bolt Size UNC |

Machine Bolt Length |

RF Stud Length |

Hole Size | ISO Stud Size |

Weight in kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | |||||||||

| 1/2 | 15 | 90 | 9.6 | 34.9 | 2 | 60.3 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.9 |

| 3/4 | 20 | 100 | 11.2 | 42.9 | 2 | 69.9 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 50.8 | 2 | 79.4 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 63.5 | 2 | 88.9 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 73 | 2 | 98.4 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.8 |

| 2 | 50 | 150 | 17.5 | 92.1 | 2 | 120.7 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 104.8 | 2 | 139.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 127 | 2 | 152.4 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 4.1 |

| 3 1/2 | 90 | 215 | 22.3 | 139.7 | 2 | 177.8 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 4 | 100 | 230 | 22.3 | 157.2 | 2 | 190.5 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 7.7 |

| 5 | 125 | 255 | 22.3 | 185.7 | 2 | 215.9 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 9.1 |

| 6 | 150 | 280 | 23.9 | 215.9 | 2 | 241.3 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 11.8 |

| 8 | 200 | 345 | 27 | 269.9 | 2 | 298.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 20.5 |

| 10 | 250 | 405 | 28.6 | 323.8 | 2 | 362 | 12 | 7/8 | 100 | 115 | 1 | M24 | 32 |

| 12 | 300 | 485 | 30.2 | 381 | 2 | 431.8 | 12 | 7/8 | 100 | 120 | 1 | M24 | 50 |

| 14 | 350 | 535 | 33.4 | 412.8 | 2 | 476.3 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 64 |

| 16 | 400 | 595 | 35 | 469.9 | 2 | 539.8 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 82 |

| 18 | 450 | 635 | 38.1 | 533.4 | 2 | 577.9 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 100 |

| 20 | 500 | 700 | 41.3 | 584.2 | 2 | 635 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 130 |

| 24 | 600 | 815 | 46.1 | 692.2 | 2 | 749.3 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 196 |

Uses of Blind Flanges

Blind flanges are used in various applications, including oil and gas, chemical, and petrochemical industries. They are commonly used as end closures of piping systems or vessels, providing a tight seal against pressure, temperature, and corrosion. Blind flanges are also used to install valves, pressure gauges, and other equipment.

Types of Blind Flanges

Blind flanges come in different types, including standard blind flanges, spectacle blind flanges, and paddle blind flanges. Standard blind flanges have a solid disk with a bolt hole pattern, whereas spectacle blind flanges are designed with a removable section that a blind flange or a spacer flange can replace. Paddle blind flanges, on the other hand, are designed with a solid disk and an attached paddle, which can be rotated to open or close the opening.

Materials of Blind Flanges

Blind flanges are made from various materials, including carbon steel, stainless steel, and alloy steel. The choice of material depends on the specific application, including the fluid to be transported, the temperature and pressure of the system, and the level of corrosion resistance required.

Installation and Maintenance of Blind Flanges

The installation of blind flanges requires careful handling and the use of proper tools and equipment. Before installation, the flange face should be cleaned and inspected for any defects or damage. The gasket should be carefully placed over the sealing surface, and the bolts should be tightened to the appropriate torque. Maintenance of blind flanges involves regular inspection and replacement of gaskets, bolts, and other components to ensure that they are in good working condition.

Conclusion:

Blind flanges are essential components in piping and vessel systems. They provide a reliable and efficient means of sealing off openings and isolating parts of the system from the rest. Blind flanges come in various sizes, materials, and types, making them suitable for different applications. Proper installation, maintenance, and inspection of blind flanges are critical for ensuring piping and vessel systems’ safe and efficient operation. If you have any questions or need assistance selecting or installing blind flanges, contact a professional in the field.

A passionate metal industry expert and blogger. With over 5 years of experience in the field, Palak brings a wealth of knowledge and insight to her writing. Whether discussing the latest trends in the metal industry or sharing tips, she is dedicated to helping others succeed in the metal industry.