When it comes to connecting pipes, flanges are an essential component. Among the several types of flanges available in the market, weld neck flanges hold significant importance due to their exceptional strength, durability and leak-proof nature. But only some people are well-versed with these types of flanges. Therefore, this blog post will explain in detail what are weld neck flanges, their dimensions, uses and types.

What is Weld Neck Flanges?

Weld Neck Flanges are pipe flanges designed with a long tapered hub and a butt-welded attachment to the mating pipes. They provide high performance, strength, and reliability for indoor and outdoor applications. The design of weld neck flanges eliminates stresses in the connection zone, which improves leak-tightness even under extreme temperatures. Additionally, they’re often used when long service is required from components.

Understanding Weld Neck Flanges:

Weld neck flanges are a flange welded to the pipe’s neck to provide a smooth transition between the pipe and the flange. Choosing the right size of the weld neck flange is essential to ensure maximum stability and prevent movements due to pressure or temperature variations. Weld neck flanges are available in various materials like Stainless Steel, Carbon Steel, Duplex Steel, and Alloy Steel.

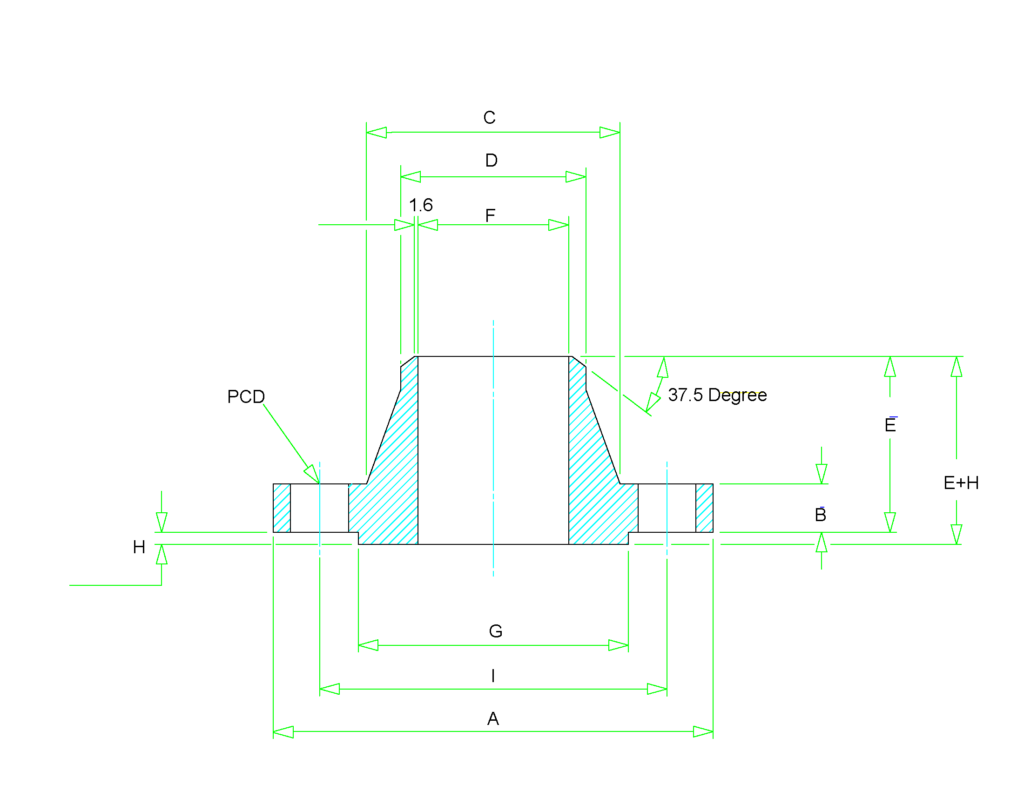

Dimensions of Weld Neck Flanges:

| Size in Inch | Size in mm | Outer Diameter | Flange Thickness | Hub OD | Weld Neck OD | Welding Neck Length | Bore | RF Diameter | RF Height | PCD | Weld Face |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | ||

| 1/2 | 15 | 90 | 9.6 | 30 | 21.3 | 46 | Welding Neck bore is derived from the pipe schedule | 34.9 | 2 | 60.3 | 1.6 |

| 3/4 | 20 | 100 | 11.2 | 38 | 26.7 | 51 | 42.9 | 2 | 69.9 | 1.6 | |

| 1 | 25 | 110 | 12.7 | 49 | 33.4 | 54 | 50.8 | 2 | 79.4 | 1.6 | |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 42.2 | 56 | 63.5 | 2 | 88.9 | 1.6 | |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 48.3 | 60 | 73 | 2 | 98.4 | 1.6 | |

| 2 | 50 | 150 | 17.5 | 78 | 60.3 | 62 | 92.1 | 2 | 120.7 | 1.6 | |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 73 | 68 | 104.8 | 2 | 139.7 | 1.6 | |

| 3 | 80 | 190 | 22.3 | 108 | 88.9 | 68 | 127 | 2 | 152.4 | 1.6 | |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 101.6 | 70 | 139.7 | 2 | 177.8 | 1.6 | |

| 4 | 100 | 230 | 22.3 | 135 | 114.3 | 75 | 157.2 | 2 | 190.5 | 1.6 | |

| 5 | 125 | 255 | 22.3 | 164 | 141.3 | 87 | 185.7 | 2 | 215.9 | 1.6 | |

| 6 | 150 | 280 | 23.9 | 192 | 168.3 | 87 | 215.9 | 2 | 241.3 | 1.6 | |

| 8 | 200 | 345 | 27 | 246 | 219.1 | 100 | 269.9 | 2 | 298.5 | 1.6 | |

| 10 | 250 | 405 | 28.6 | 305 | 273 | 100 | 323.8 | 2 | 362 | 1.6 | |

| 12 | 300 | 485 | 30.2 | 365 | 323.8 | 113 | 381 | 2 | 431.8 | 1.6 | |

| 14 | 350 | 535 | 33.4 | 400 | 355.6 | 125 | 412.8 | 2 | 476.3 | 1.6 | |

| 16 | 400 | 595 | 35 | 457 | 406.4 | 125 | 469.9 | 2 | 539.8 | 1.6 | |

| 18 | 450 | 635 | 38.1 | 505 | 457.2 | 138 | 533.4 | 2 | 577.9 | 1.6 | |

| 20 | 500 | 700 | 41.3 | 559 | 508 | 143 | 584.2 | 2 | 635 | 1.6 | |

| 24 | 600 | 815 | 46.1 | 663 | 610 | 151 | 692.2 | 2 | 749.3 | 1.6 |

Uses of Weld Neck Flanges:

Weld neck flanges are widely used in high-pressure tolerance applications and are subject to considerable pressure fluctuations. Some common uses of weld neck flanges include chemical processing plants, power generation plants, and construction sites. In addition, weld neck flanges are used in piping systems that need frequent dismantling and reassembling.

Types of Weld Neck Flanges:

Depending on the application requirements, there are four major types of weld neck flanges.

Standard Long Weld Neck Flange: These flanges are used in low-pressure applications and are suitable for small pipes.

Extra Long Weld Neck Flange: These flanges are excellent for high-pressure applications and heavy-duty piping systems. It is ideal for vessels with high nozzle loads.

Integral Flange: These flanges connect standard valves, pumps and other piping components where welding isn’t possible or practical.

Nipoflange: These flanges are designed for piping systems where branches must be connected to the pipe without using a tee.

Advantages of Weld Neck Flanges:

The most significant advantage of weld neck flanges is their durability and leak-proof nature. These flanges offer an extended lifespan, making them an excellent investment for any piping system. They also relieve stress, reducing the possibility of cracking or other damage caused by thermal expansion.

Conclusion:

Weld neck flanges are integral to the piping systems and offer several advantages over other flanges. Knowing the right dimension, type and applications is crucial to getting the best results out of your piping system. Understanding all the aspects of weld neck flanges can help you decide which flange type to use and how to maximise its performance.

A passionate metal industry expert and blogger. With over 5 years of experience in the field, Palak brings a wealth of knowledge and insight to her writing. Whether discussing the latest trends in the metal industry or sharing tips, she is dedicated to helping others succeed in the metal industry.